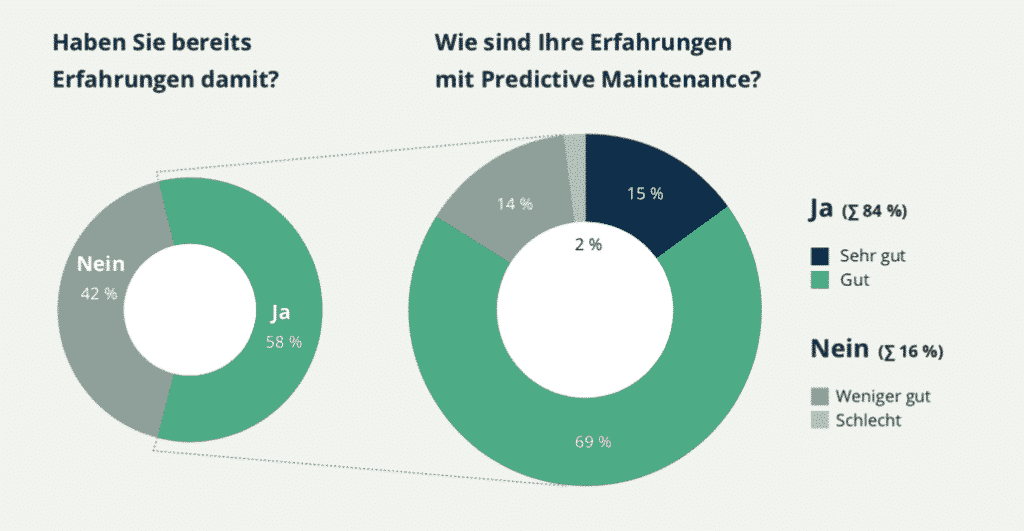

The "German Industry 4.0 Index 2018" is an annually conducted study that determines the current status of developments in the context of digital transformation. In particular, the results on Predictive Maintenance However, this does give pause for thought. On the one hand, predictive maintenance is one of the most prominent use cases of Industrie 4.0. On the other hand, it is precisely this use case that falls short of companies' expectations.

The study "Predictive Maintenance" by the VDMA and the management consultancy Roland Berger also comes to the conclusion that only 40 per cent of companies use predictive maintenance. Precisely because we have had extremely positive experience with many predictive maintenance projects, we see great, underutilised potential in this. For this reason, we want to ask once again what the critical Success factors of predictive maintenance and in which concrete Scenarios it is worthwhile to use it.

Inhaltsverzeichnis

Conventional Maintenance approaches are no longer up to date

Maintenance was used to be carried out according to fixed, predefined Intervals carried out. In many cases, this is still the case today. However, this practice is extremely time-consuming and leads above all to the fact that even machines are maintained that are still in perfect working order. The decisive problem is that during the maintenance period, the machines are not available for production or use during the maintenance period.

Such conventional maintenance and servicing approaches therefore cause unnecessary costs. In addition approach does not rule out the possibility of unexpected machine failures. of machines. These can lead to considerable economic losses, because spare parts are only ordered when the machine is no longer functioning. no longer works. The goal of a maintenance approach for the digital Age the Industry 4.0 must therefore find a solution to these two challenges. And this solution is called: Predictive Maintenance.

The Basics for Predictive Maintenance

The foundations for the predictive maintenance approach are data and Data analyses. These provide the basis for planning and carrying out maintenance. The prerequisite for this is monitoring data provided by sensors that are placed in the machines for this purpose. The amount of data that accumulates in this process is sometimes enormous (Big Data). This data is examined in real time for conspicuous patterns. This is done by first defining which values represent the Normal operation define. Based on this different Sample which indicate the failure of a certain component or a malfunction of the engine can be detected.

Critical success factors

First and foremost, a Predictive Maintenance Use Case is an important opportunity to Data Skills in their own organisation. Without the corresponding know-how and experience with data projects, either an unrealistic Expectation horizon or the results fall short of expectations.

Ensuring a high level of Data quality is critical for the success of Data projects overall and especially of predictive maintenance projects. It is advisable to always collect several control measurements at the same time for each data collection point in order to quickly identify or exclude incorrect measurements.

Reading Tip: The introduction of a Data catalogue can also be an important building block for successful data-driven use cases.

Another key success factor for predictive maintenance is related to the specific question and the Business model of the respective customer. Predictive maintenance is not purely an end in itself, but must be integrated in the Overall context be considered and evaluated. This can be analysed in a use case workshop, for example, which we offer precisely for this purpose.

The Advantages of Predictive Maintenance

However, the approach described so far only represents the simplest functional principle according to which predictive maintenance works. Within the framework of the numerous Use Caseswhich we have already successfully carried out in this context, we were able to establish that the concrete questions in the companies were often much more specific or went beyond this. Nevertheless, a whole series of Advantages that predictive maintenance brings:

- Lifetime of machines and systems is prolonged and investment costs are thereby

reduced

- Damage can be identified before they arise

- Repairs can be better planned and implemented

- Causes can be used on Component level be determined

- Data provide feedback for manufacturers and producers to improve the Quality Improve in the long term

Predictive maintenance can also be the basis for new Services and Business models deliver. For example, plant and machinery manufacturers can offer new service offer new service offerings in addition to their existing business model.

Use Case: Telematics service for MAN

How much a maintenance use case must be embedded in the overall context of a company. The concrete case of one of our customers - the truck manufacturer truck manufacturer MAN. This company had to struggle time and again with the fact that some of its fully loaded, for example, due to injector damage. injector damage, for example. The breakdown resulted in direct costs for the repair for the repair as well as indirect costs for convention penalties and a downgrading in the downgrade in the quality ranking. Our solution was to develop and and implementation of a telematics service in series production. This served us as a data provider for Predictive analytics for preventive detection of a breakdown or defect.

To this end, we use data mining methods to extract the Telematics data of the vehicles to preventively detect failures in order to proactive to be able to react to it. The statistical alignment procedures and data mining methods were analysed and predicted using the example of the ignition coil and the injectors. For our customer, we were thus able to statistically predict certain error patterns using the telematics data. In this way we achieved:

- Avoidance

fromPanelsthroughtheproactive Monitoring the Telematics data

- Early Detection from rising in the field Quality problems

- Reduction the Warranty and Goodwill costs as well asdrastic Increase the Customer satisfaction

With this and other use cases, we are repeatedly finding the great value that predictive maintenance delivers compared to conventional solutions. The added value does not only come from avoiding repair costs. repair costs. Above all, the resulting increase in reliability and customer satisfaction of the customers is more than just an indirect side-effect of predictive maintenance.

0 Kommentare